Introduction

Replenishment is a complex subject that requires taking many parameters into account. It is necessary to assess the quantity of items in stock, available space, consumption and delivery forecasts, the valuation of items, the promised service level, as well as external factors such as weather and seasonality.

Yet, it is a crucial issue for businesses. Insufficient stock can lead to the loss of business opportunities, production halts, or even the stalling of research projects.

It is therefore essential to have a clear vision to know when and how to replenish efficiently.

The different ways to manage replenishment

In Odoo, there are several methods to manage replenishment based on the specific needs of the company.

- Replenishment on demand This method is ideal for items that you do not wish to stock. Every time a need arises, whether for a sale or a research project, Odoo generates a manufacturing or purchase order proposal. The item is never kept in stock but is purchased on demand, then directly sold or used.

- Replenishment in case of insufficient stock This method is suitable for items that are stored sporadically. If stock is available, Odoo consumes it. In case of insufficiency, the system automatically proposes a replenishment to meet the demand.

- Replenishment according to the min-max rule This method applies to items that you want to keep in stock continuously. For these items, a minimum and maximum quantity is defined. As soon as the stock falls below the minimum threshold, Odoo generates a replenishment proposal to bring the stock level back to the desired maximum.

Inventory management tools in Odoo

Odoo offers several tools to facilitate inventory management.

The replenishment table

The replenishment table is an essential tool for monitoring supply delays and possible delivery dates. Each time you access the system, Odoo calculates forecasts for your items. If an item is at risk of going into negative stock, Odoo automatically generates a replenishment proposal.

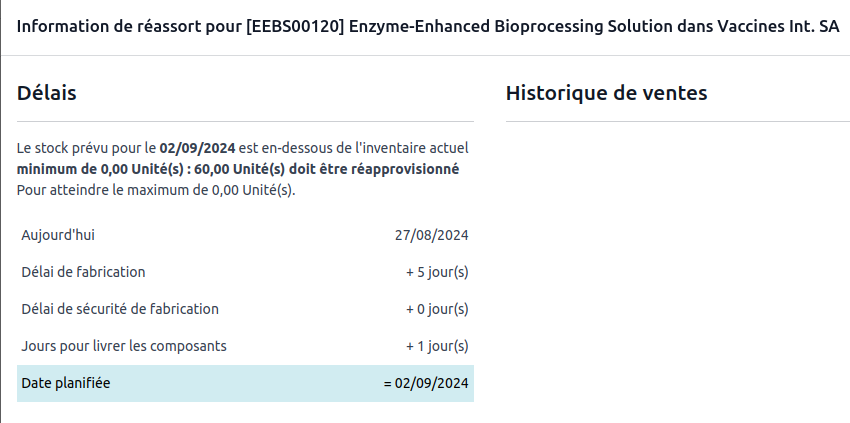

For example, in the illustration below, we have 5 units in stock of the Enzyme-Enhanced Bioprocessing Solution. Two deliveries are scheduled: one on 08/30 and the other on 09/02. The production of this item requires 5 days, but no production is currently planned. When accessing the replenishment table, Odoo detects a risk of delivery delay and proposes generating a replenishment for the 60 missing units.

An explanatory pop-up is also available to provide details on the timelines.

Odoo's MPS

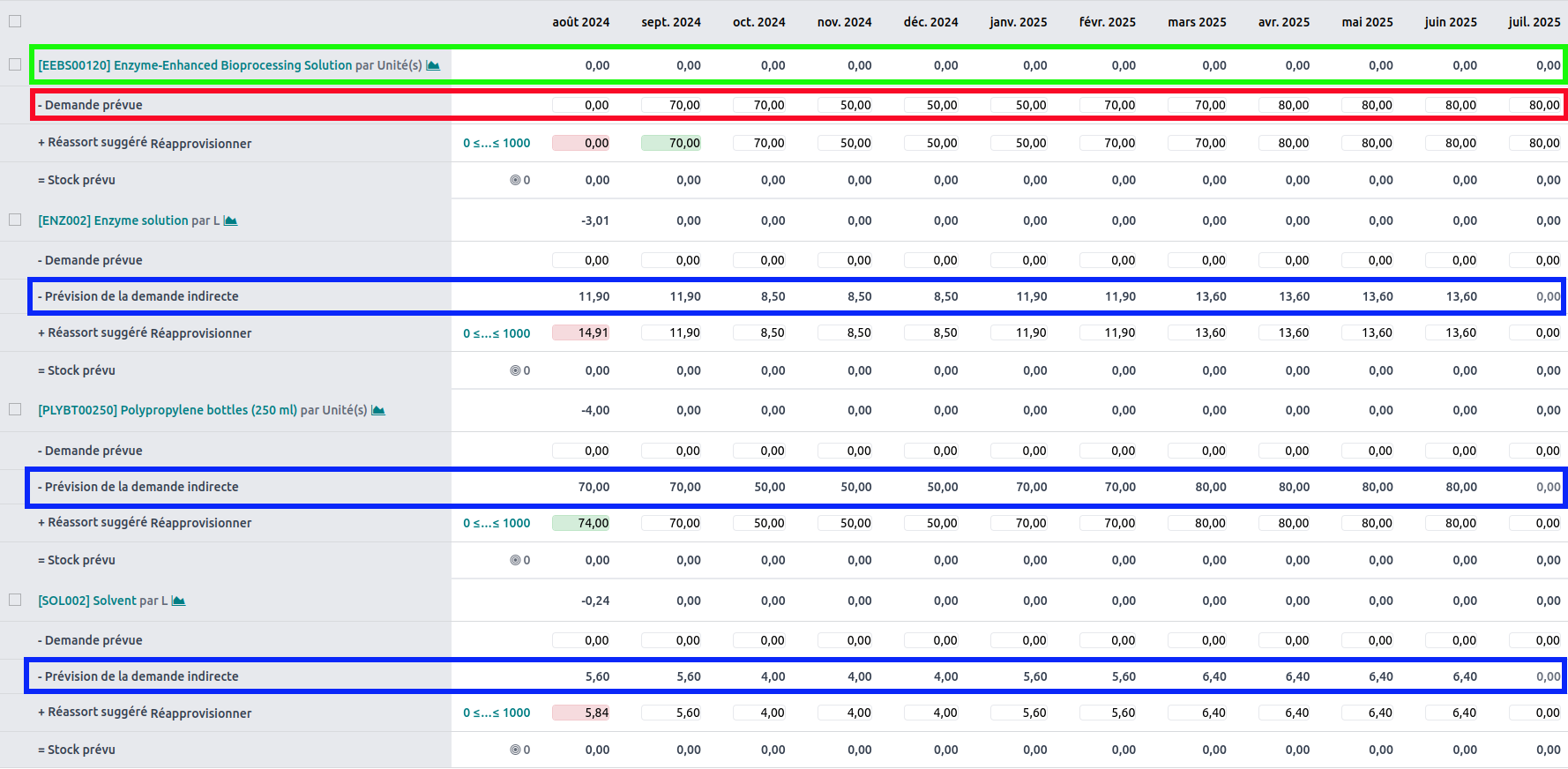

This tool allows for simulating production over a defined period. For example, I have configured a period of 12 months, which gives me the opportunity to enter demand forecasts for each of my items during this time.

Odoo displays the projected stock status at the beginning of each period on the green line, based on the entries and exits already recorded in the system. On the red line, I have manually entered the forecasted demands for the Enzyme-Enhanced Bioprocessing Solution item.

The blue lines show the indirect demand that this forecast generates for the components of the item in question.

For each item, Odoo offers a replenishment solution. However, this tool has some limitations. Entering demand forecasts for each item can be tedious, and it becomes even more challenging to maintain over time. Nevertheless, it can be useful for a limited number of items, where manual management remains feasible.

The limitations of Odoo

Despite its many features, Odoo has some limitations. It does not allow for predictive replenishments, relying solely on the sales recorded in the system. Additionally, it does not enable the simulation of multiple replenishment scenarios to compare delivery times and choose the best option.

Odoo also does not take into account the availability of all resources. It is impossible to produce items in parallel that require the same resources, whether they are material or human.

Frepple : a complementary tool

To overcome these limitations, there is Frepple, an advanced planning and replenishment tool that integrates seamlessly with Odoo. Frepple goes far beyond Odoo's standard features, offering predictive capabilities and advanced simulation. The developers of Frepple are recognized experts in this field and have written an article detailing the shortcomings of Odoo [lien].

Combined with Odoo and Smart Biotech, Frepple enables the optimization of inventory management and planning in the biotechnology sector.

Conclusion

Replenishment management is an essential component to ensure business continuity and meet customer needs. As we have seen, Odoo offers effective methods for managing replenishment, whether it is to respond to immediate demand, maintain appropriate stock levels, or react quickly in case of shortages. However, these features, while robust, have their limitations, particularly regarding forecasting and advanced planning.

This is where complementary tools like Frepple come into play, offering predictive and simulation solutions that go well beyond Odoo's standard capabilities. By integrating Frepple with Odoo and Smart Biotech, companies in the biotechnology sector can not only bridge these gaps but also optimize their supply chain, ensuring better responsiveness, more precise resource management, and anticipation of future needs.

To find out more about the solution, visit our product page.

Replenishment management