The cosmetics industry is evolving at a rapid pace. Trends change quickly, expectations for transparency keep multiplying, and sustainability has become the new standard.

In this context, every decision, from ingredient selection to batch validation, has a direct impact on quality, compliance, and the trust consumers place in your brand.

Our teams support cosmetic companies that share the same ambition: to innovate while maintaining full control over their quality processes.

Innovate fast, master better: the everyday challenge of cosmetics

You experience it every day: in the cosmetics industry, everything moves fast. A new texture idea, an emerging active ingredient, a trend from social media, and immediately the inspiration must become a product. The formula needs adjusting, tests must be validated, and the launch planned. Product lines evolve constantly, and coordination between R&D, production, and quality control becomes a balancing act. This agility is a strength for the industry, but it requires flawless rigor. Every ingredient, every stability test, and every regulatory validation matters.

Cosmetic regulations, from Regulation (EC) No. 1223/2009 to international distributor standards, define every stage of the product lifecycle. Far from being a constraint, this framework is an essential guide that ensures the safety, reliability, and reputation of brands that comply with precision.

At the same time, the shift toward more responsible beauty is transforming practices: sourcing natural ingredients, reducing packaging, and being transparent about formulas and testing. Quality teams have become key players in this transformation, ensuring a balance between innovation and sustainability.

And then there are the consumers: passionate, informed, and highly connected. They want to know the origin of ingredients, understand the promises displayed on packaging, and be confident in the traceability and safety of the products they apply to their skin. This demand for transparency is redefining cosmetic quality. It is no longer only about technical compliance but a genuine commitment of trust between the brand and its customers.

How Smart Quality supports cosmetic industry players every day

In the cosmetics sector, digitalizing quality management is no longer optional but essential. The question is not whether to go digital, but how to do it intelligently. That is precisely the goal of Smart Quality, our solution developed by Idealis Solutions.

Designed with and for professionals in the field, Smart Quality helps your teams gain visibility, simplify compliance, anticipate risks, and strengthen collaboration.

1. Clear and intuitive traceability to stay in control

In the cosmetics world, where formulas evolve quickly and production runs multiply, knowing exactly where each batch stands is a daily challenge. From the reception of a natural active to stability testing and final packaging, every step must be traced, verified, and documented.

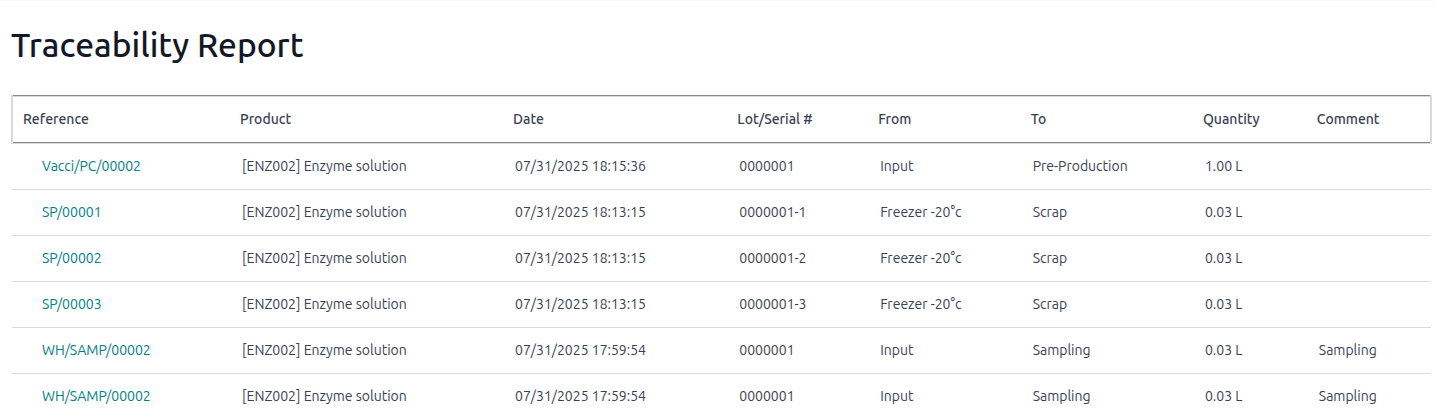

Smart Quality centralizes all this information in one intuitive and visual platform. You can track batch progress in real time, view certificates of analysis for raw materials, check compliance statuses, and trace the complete journey of an ingredient to the finished product.

For example : if a variation is detected in the viscosity of a new moisturizing cream, Smart Quality immediately identifies the batch of glycerin involved, its supplier, and all other productions using the same material. Within seconds, your teams can act, correct, and document without disrupting production.

This clear and instant view gives you full control over your manufacturing processes, helps you anticipate deviations, and ensures flawless traceability in an environment with high regulatory and commercial standards.

2. Simplified compliance without adding complexity

In cosmetics, compliance is not just an administrative step; it is a prerequisite for market access. Every raw material, production batch, and packaging element must be supported by certificates of analysis, technical sheets, test reports, and proof of conformity. In practice, this means managing hundreds of documents that must be collected, organized, and updated.

Smart Quality automates this complex documentation management. Certificates, analyses, and reports are automatically linked to their corresponding batches, ensuring reliable, up-to-date, and easily accessible records.

Imagine a supplier audit : the auditor requests proof of compliance for a preservative or pigment used in a specific range. With a single click, Smart Quality displays the certificate of analysis, the reception date, the supplier, and the complete traceability of the batch. No manual searching, no uncertainty; compliance becomes a seamless, integrated process for your quality and regulatory teams.

3. Automated quality controls for greater reactivity

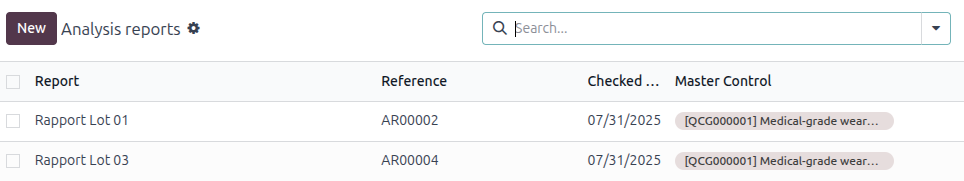

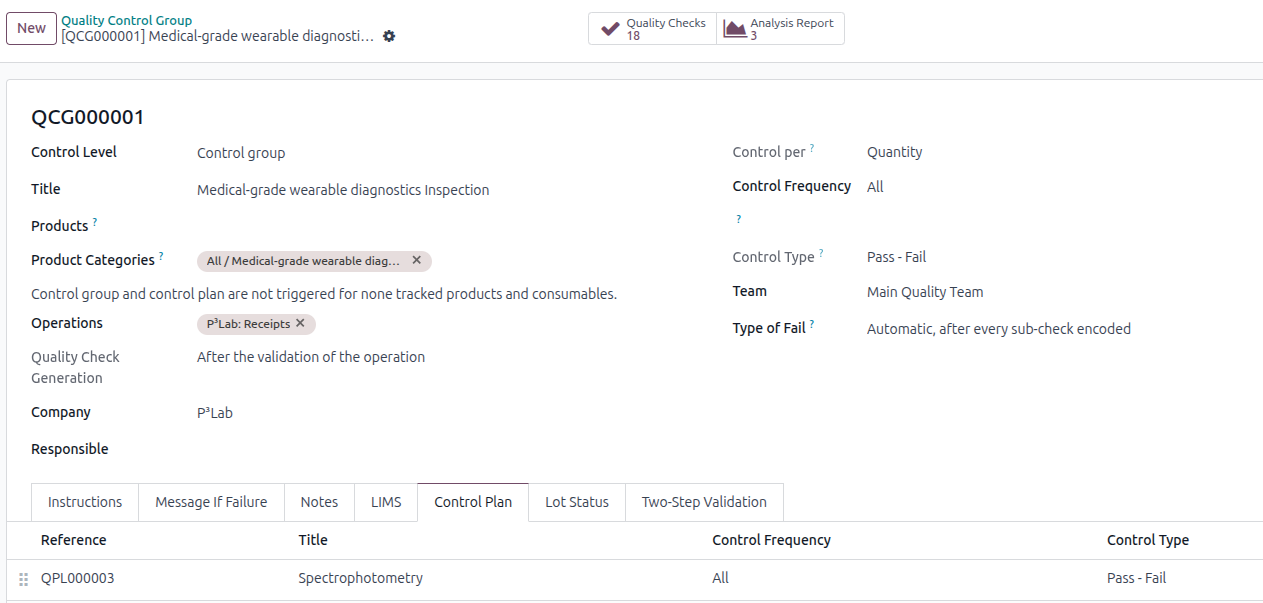

Between stability tests, microbiological checks, and packaging validations, cosmetic laboratories handle dozens of control points every day. Planning these checks manually quickly becomes time-consuming, especially with multiple production lines and complex formulations.

Smart Quality automates this planning using your own criteria. The system automatically generates control plans tailored to each product, based on your internal procedures and regulatory requirements.

For example, when you launch a new fragrance, Smart Quality can automatically trigger enhanced control for the first raw material batches. Your teams gain time, consistency, and reliability, focusing on analysis rather than logistics.

The result is a more responsive laboratory, dedicated to quality and innovation.

4. Anticipating deviations and driving continuous improvement

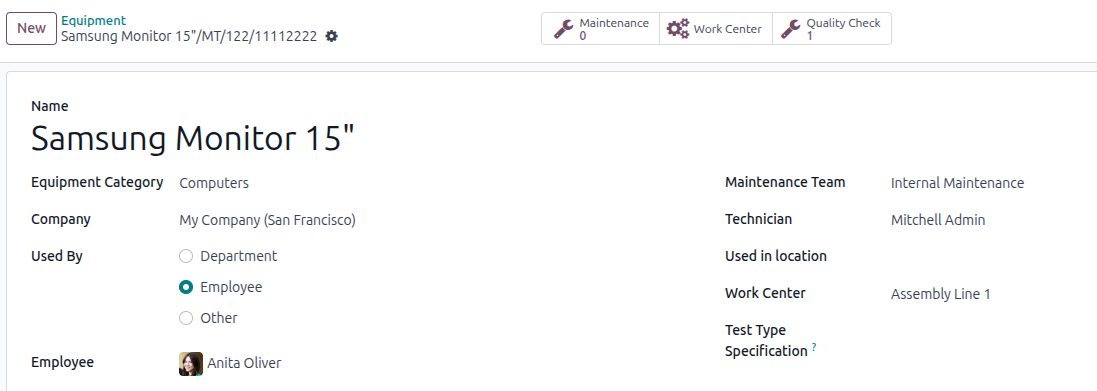

Even in the most rigorous laboratories, a quality deviation linked to a poorly calibrated piece of equipment can occur: a color variation, a change in scent, a texture instability. What matters is not the error itself but the ability to detect and act quickly.

Smart Quality includes smooth equipment and maintenance management, enabling full reverse traceability. When an issue is detected, for example a slightly grainy cream batch, the system instantly identifies the equipment used, the raw materials involved, and any other impacted productions. Corrective actions are recorded and tracked until resolution.

Recurring analyses reveal trends and help anticipate risks.

Smart Quality transforms reactivity into continuous improvement, delivering controlled, predictive, and sustainable quality.

Smart Quality at the heart of your quality culture

Behind every digital transformation lies a human story. The Idealis team relies on proximity, listening, and co-design to make Smart Quality more than just a tool. It becomes a trusted partner at the core of your quality culture. From needs assessment to training, our goal is simple: to make your teams autonomous, confident, and high-performing in managing quality.

👉 Discover how Smart Quality can support your vision of sustainable quality and contact our experts at Idealis Solutions for a personalized demonstration.Contact us

Traceability and quality in the cosmetics industry: making innovation a sustainable driver with Smart Quality